by Alcée Montfort | Mar 29, 2022 | World of watchmaking

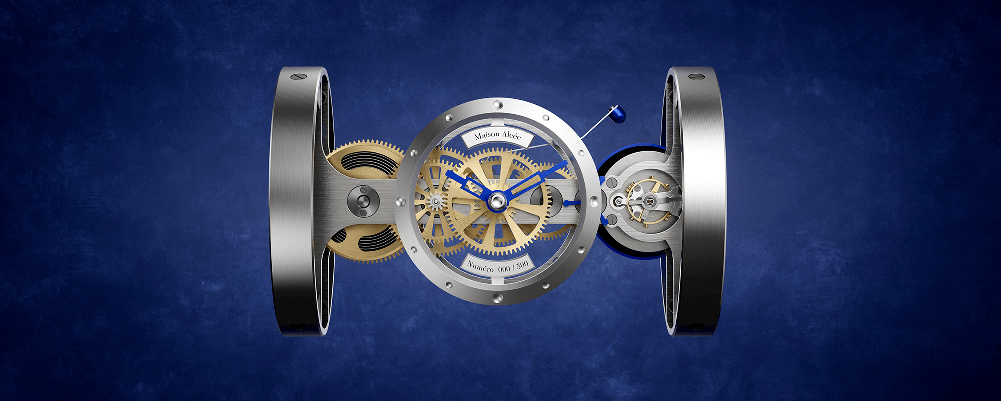

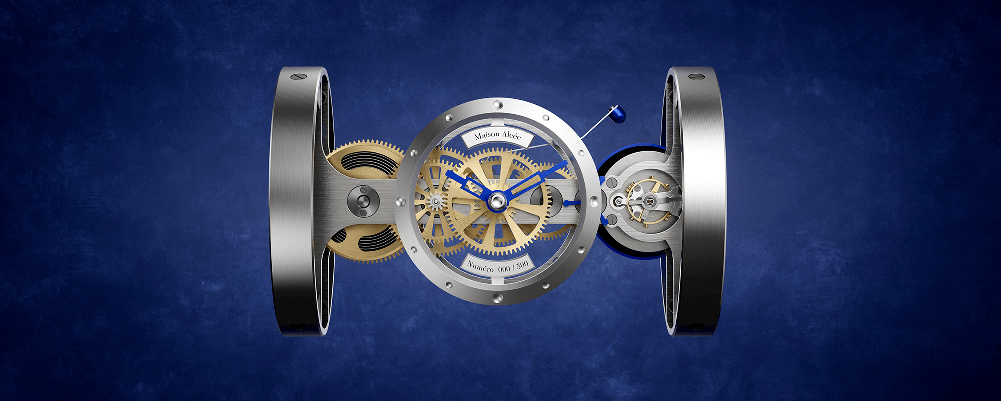

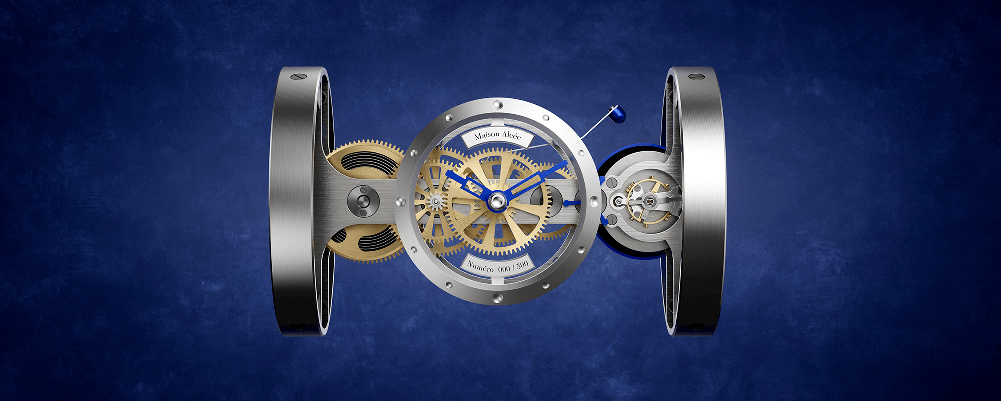

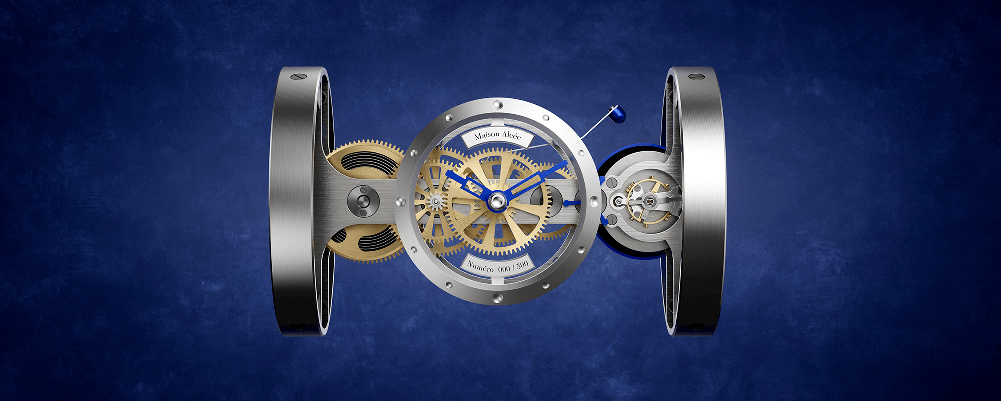

The clocks Maison Alcée takes you on a discovery of an object sometimes perceived as obsolete: the clock. Discover the history of this timepiece through the ages. Pendulum clocks The great discoveries, the sixteenth century: The pendulum clock or simply...